Influence of side lobe effect on ultrasonic sensor installation

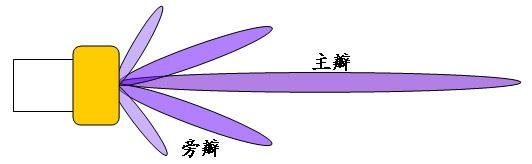

Influence of side lobe effect on ultrasonic sensor installation. The largest beam of radiation is called the main lobe, and the small beams next to the main lobe are called side lobes.

The pattern usually has two or more lobes, of which the lobe with the highest radiation intensity is called the main lobe. And the remaining lobes are called side lobes or side lobes.

The angle between two points at which the radiation intensity is reduced by 3 dB (half the power density) on both sides of the maximum radiation direction of the main lobe is defined as the lobe width. Also known as beam width or main lobe width or half power angle.

The narrower the lobe width, the better the directivity. The longer the action distance, and the stronger the anti-interference ability.

The side lobes spread the sound energy and increase the attenuation.

The direction diagram is as follows:

Installation requirements of Ultrasonic Sensor

When installing the sensor, do make sure to install it perpendicular to the liquid surface to be measured. And ensure that it is stable without tilting and displacement.

If there is a pipeline in the tank mouth, the probe should be extended out of the nozzle or parallel to the nozzle to eliminate the interference caused by the side lobe effect.

Three common tank installation requirements are described below:

Grooved container:

1. The support frame should be firm and reliable.

2. The height of the intersection line of the beam emitted by the probe and the tank wall must be less than or equal to the minimum height of the liquid level to be measured.

3. The installation height should be within the required range.

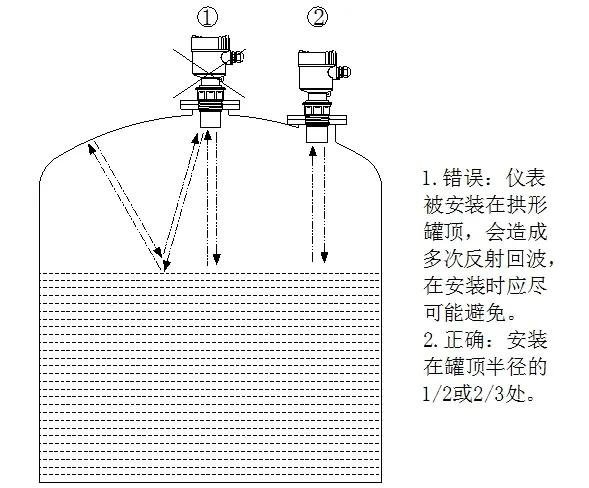

Arched container:

The meter cannot be installed on a vaulted ceiling. It should be installed at 1/2 or 1/3 of the radius of the ceiling.

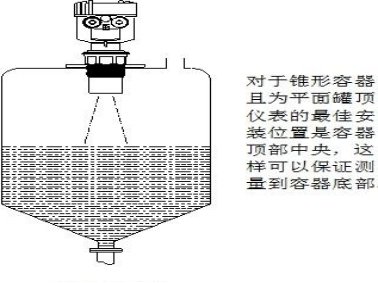

Conical container:

For a conical vessel with a flat tank top. The best installation position for the meter is the center of the top of the vessel. Which ensures that the measurement reaches the bottom of the vessel.

Related Guides