Influence of Dielectric Constant on Radar Level Meter. “Low dielectric constant liquid measurement, not suitable for radar level gauge”. Inadvertently, we hear this all the time. In fact, when I first entered the industry, I thought so too.

After a long time and understanding more, I realized that this statement is a bit one-sided. Let’s discuss it in detail. What Is Dielectric Constant?

The dielectric constant is the main parameter reflecting the dielectric properties or polarization properties of the piezoelectric smart material dielectric under the action of an electrostatic field.

Usually denoted by ε. Different applications of piezoelectric elements have different requirements for the dielectric constant of piezoelectric smart materials.

When the shape and size of the piezoelectric smart material are certain. The dielectric constant ε is determined by measuring the intrinsic capacitance CP of the piezoelectric smart material.

Influence of Dielectric Constant on Radar Level Meter

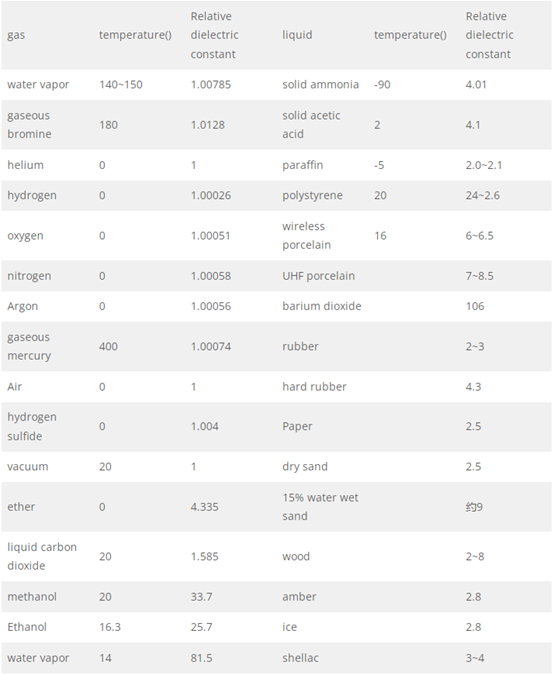

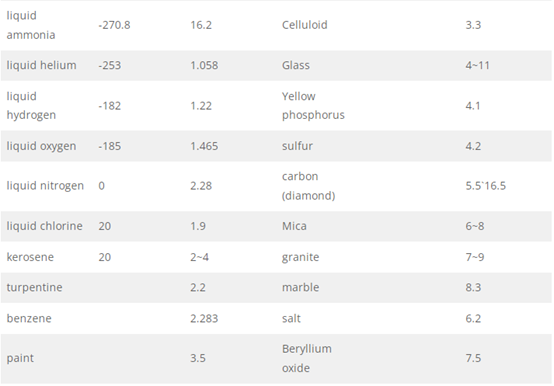

Commonly Used Dielectric Constant Table

Dielectric Constants Of Common Liquids

The relative permittivity of common solvents is at room temperature and the test frequency is 1KHz.

- H2O (water) 78.5

- HCOOH (formic acid) 58.5

- HCON (CH3) 2 (N,N-dimethylformamide) 36.7

- CH3OH (methanol) 32.7

- C2H5OH (ethanol) 24.5

- CH3COCH3 (acetone) 20.7

- n-C6H13OH (n-hexanol) 13.3

- CH3COOH (acetic acid or acetic acid) 6.15

- C6H6 (benzene) 2.28

- CCl4 (carbon tetrachloride) 2.24

- n-C6H14 (n-hexane) 1.88

- n-C4H10 (No. 4 solvent) 1.78

Influence Of Dielectric Constant On Guided Wave Radar Level Meter

From the point of view of process conditions, the dielectric constant of the medium to be measured plays a very important role in the measurement of guided wave radar as a known condition.

According to the electrical properties of the dielectric constant, it is roughly divided into three categories: non-polar substances (εr<2.8), weakly polar substances (2.8≤εr≤3.6), polar substances (εr>3.6) .

For liquefied petroleum gas, petroleum, gasoline or other hydrocarbons in petrochemical plants, and petrochemical products, 1.4≤εr≤4.0.

Alcohol, organic solvent, oil-water mixture, etc., 4.0≤εr≤10.0.

Conductive liquids, such as water-based solutions, dilute acids and bases, εr>10.0.

The Guided Wave Radar Level Meter can measure gas/liquid, gas/solid, and liquid/liquid two-phase interfaces.

Ideal for measuring liquid/liquid interfaces, such as oil-water interfaces.

The Guided Wave Radar Level Meter emits low-energy pulsed microwaves that are sent down the probe at the speed of light. At the interface between the probe and the medium, a considerable proportion of microwave energy is reflected back to the transmitter through the probe to receive the first echo signal.

A certain percentage of the pulses will continue down the probe, traversing the upper low dielectric constant medium until it is reflected on the lower medium surface and the transmitter receives the second echo.

To measure the boundary, the minimum thickness of the upper medium is 10-20 cm, so that the echoes of the two liquids can be distinguished. The maximum thickness of the upper dielectric depends on its dielectric constant.

The dielectric constant of the liquid in the upper layer is relatively low, and the difference between the dielectric constants of the upper layer and the lower layer liquid is required to be greater than 10, and the upper layer medium εr<3, the lower layer medium εr>20. Only in this way can the obvious reflection effect be obtained. Both level and interface can be measured simultaneously.

The smaller the dielectric constant of the medium, the greater the amplitude of the reflected signal. For the medium with low dielectric constant (1.2≤εr≤2.5), the guided wave radar level gauge can be selected for powdery or volatile medium.

Some substances hinder or absorb electromagnetic waves in the gas phase, and there are substances in the gas phase that weaken electromagnetic waves.

For example, dust, powder (graphite, iron alloy, etc.) with high conductivity, or volatile media. For example, the dielectric constant of liquid ammonia is at room temperature 25 ℃. It is 14.9, which is a conductive medium and can be measured effectively.

The advanced Guided Wave Radar Level Meter is especially suitable for measuring a variety of powders. And liquids with inclined liquid levels caused by vortices.

Because the reflected wave does not depend on a “flat” surface to reflect the echo, microwave safe transmission makes the medium surface condition less affected.

Disturbed liquid surface or foam formation, as well as different curved surfaces or furnace outlet will not affect the measurement. Therefore the Guided Wave Radar Level Meter also has a good measurement effect in turbulent situations.

From the perspective of measurement range, the medium with higher dielectric constant has better reflection performance and is suitable for longer measurement range. Guided Wave Radar Level Meter adopts two-wire loop power supply, 24V (DC) or 220V (AC) liquid level transmitter, low energy consumption, and meets the control level process requirements.

Influence Of Dielectric Constant On Radar Level Meter

The Radar Level Meter adopts the principle of transmit-reflection-receive. The antenna of the Radar Level Meter emits electromagnetic waves.

These electromagnetic waves are reflected by the surface of the measured object and then received by the antenna. The time from emission to reception of electromagnetic waves is proportional to the distance to the liquid surface.

In the measurement of Radar Level Meter, the measured medium needs to provide sufficient radar reflection signal. In general, the higher the dielectric constant, the stronger the reflected signal.

The farther away the target is, the greater the intensity of the reflection is required. In order to have sufficient signal back to the radar transmitter.

When the radar wave reaches the liquid level surface and is reflected. The radar wave will be absorbed and attenuated.

When the attenuation is too much, the radar level gauge will not receive enough signal, resulting in inaccurate measurement.

This is the dielectric constant of the measured medium. Effects of radar level gauge measurements.

From this point of view, the dielectric constant has an effect on the Radar Level Meter measurement. However, this problem has been well resolved.

The Radar Level Meter can also perform interface measurements, especially on oil-water interfaces.

Principle: When measuring the interface, the part of the pulse that is not reflected on the surface of the upper product will continue down to the surface of the lower product, and then be reflected back.

The requirements for the dielectric constant when the Radar Level Meter measures the interface are as follows:

- The dielectric constant of the upper product must be known and must not be changed;

- The difference between the dielectric constants of the two products must be greater than 6;

- Mainly used in the interface between oil-water liquid and water/water-like liquid with lower dielectric constant of the upper layer (<3) and higher dielectric constant of the lower product (>20).

Related Guides